| |

|

|

| |

|

|

| |

|

|

|

| |

|

|

| |

|

| Background:

|

|

| The wire winding machine shown opposite is

part of a pre-stressed pipe making plant in Toomebridge, N. Ireland.

This machine winds tensioned wire onto concrete pipes (dia. range

400mm ~ 1980mm up to a maximum length of 5m.) |

|

|

| |

|

|

| |

|

There are three main machinery components in the pipe plant :

- The roller suspension "making-machine" uses rotating moulds

to manufacture the core part of a pipe with a preset internal diameter and

longitudinal pre-stressed bars.

- The wire winding machine applies pre-stessing to a pipe by

wrapping pre-stressed wire around the outside of the core pipe.

- The mortar "coater" machine covers the pipe and

wire with a mortar finish to provide protection.

As part of a full machine design re-appraisal, ITI

compiled a complete set of engineering fabrication drawings for the

framework and operational components of the winder, incorporating many

refinements in comparison with the original design. In particular, the

hydraulically-operated regenerative wire-winding system was assessed with

a view to re-design using modern componentry. As a result of this, the

budget for replacement of the total machine was brought down to the level

originally quoted by contractors for supply of hydraulic machinery components

only.

ITI has since been requested to conduct a similar exercise on a second larger

wire-winder owned and operated by Macrete. As part of that contract, we

would anticipate replacement of an existing mechanical tensioning system

with a hydraulic system as specified for the smaller winder. Electronic

control of a variable displacement hydraulic motor will also improve

considerably the ease of adjustment of the machine for winding core pipes

of varying outside diameters.

|

| |

|

|

| |

|

The Wire Winding Process

|

| |

|

A 6mm high yield steel wire is wrapped several times around a tensioning wheel

which in turn is attached to a high torque hydraulic motor. Oil from the motor

is at the same time driving a second motor which turns the pipe. The rotational

torque of the two motors is then used to generate a tension in the wire as it

winds onto the outside of the rotating pipe. A second wheel moves linearly

along the length of the pipe, thus allowing the tensioned wire to be wrapped

around the pipe at the 'pitch' required. (See thumbnail animation opposite).

|

|

|

| Thumbnail animation of a wire winding machine |

|

| |

|

Back to top |

|

| |

|

|

| |

|

Background:

|

| |

|

|

Testing of engines for compliance with growing legislation is an

increasingly important element in any overall internal

combustion engine research and development programme.

Such testing has become more and more sophisticated

through recent years as demands have risen for more precise

and more extensive information on all aspects of engine

behaviour. It

would not now be uncommon, for example, for a test team to

wish to measure and record as many as sixteen simultaneous

signals for temperature, pressure, mass flow rate,

crank-position and

|

|

|

|

| |

|

force from an engine test-bed – and

this at acquisition rates of several Mega-Hertz and at

levels of accuracy of better than +/-0.5%.

This places very stringent requirements indeed on any

test cell data acquisition system, and especially where

small high-speed high performance engines are concerned. |

| |

|

|

| |

|

The Internal Combustion Engines Research Group (ICERG) of the Mechanical

Engineering Department, Q.U.B. has been involved for many

decades in the testing and development of internal combustion

(IC) engines, and particularly high performance motorcycle

engines. Through

that time, the Group has earned an extremely high worldwide

reputation in this area, having notable success in modelling of

IC engines and catalysts. To capitalise on this proven research

ICERG have teamed up with Optimum Power Technology Inc.

(Pittsburgh, USA) to market a range of powerful software tools,

now used widely by many of the big names in engine and catalyst

development..

|

| |

|

|

| |

|

|

|

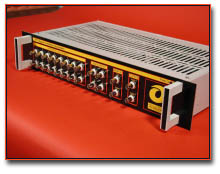

Front view of rack system

|

However, the software developed by ICERG and OPT represents only part of

the solution to the overall problem. They recognised a high

potential demand in the global market for affordable integrated

data acquisition systems.

Furthermore, they recognised that the QUB software could

form one key element in a complete and very flexible commercial

package as good as any presently available throughout the world.

For this reason, over a period of two years or so, ITI

has been leading in the development of Signal Conditioning Units

(SCUs) for a complete engine data acquisition and signal

analysis system package for use potentially in IC engine testing

cells throughout the world. (This work has been greatly assisted

by the winning of Smart grant assistance from Invest NI and DTI.)

|

| |

|

|

The high specification of such electronic

hardware, combined with a low-to-mid target price, puts great

demands on the designers. Through this and other projects, ITI has

developed expertise in many areas of electronic systems design and

product development, and have demonstrated new methods of using

existing technology coupled with new technologies to provide powerful solutions to

complex problems. The unique system features

include:

|

|

|

Rear View of rack system

|

|

|

|

|

| |

|

-

Programmable anti-aliasing filters with self-tracking, manual and by-pass

modes;

-

Programmable shaft-encoder

multiplier/interpolator to increase angular resolution to

hundredths of a degree;

-

Simultaneous Sample-and-hold on all analogue

channels;

-

Portable and Rack-mounted system formats;

-

Acquisition of 16 differential analogue

channels at up to 1.25MSPS;

-

Full PC control of system via serial interface

(upgradeable firmware).

|

| |

|

All-in-all the SCU takes advantage of low cost PC

hardware and advanced electronics to produce a unique high-speed

data acquisition system capable of sampling up to 1.25 MHz in

either time-based or angle-based mode. The system provides

automotive engineers with significant savings in both cost and

time over other available systems due to its ease of use and

unique filtering system. Its break-through software controlled

digital filtering system ensures that the correct level of

filtering is applied to prevent aliasing of the incoming signals

regardless of the engine speed. |

| |

|

Back to top |

|

| |

|

|

| |

|

Background:

|

| |

|

|

Corriboard is a popular rigid plastic material similar in structure

to corrugated cardboard. It is commonly used now to make a very wide

variety of recyclable packaging and storage containers for education and

industries such as automotive, fisheries and food etc..

For many years the client company has produced Corriboard based

products, with the majority of the box shaped products requiring a

seam to be welded shut to form a stable box. |

|

The technique used for several years was based on spot-welding using

ultrasonics. While this method gave a satisfactory mechanical joint, it did

leave unsightly depressions in the seam where the ultrasonic heads pressed

together. The company was finding that some customers were

hesitant about the products as a result. The technique of using ultrasonic heads was also

inherently

slow and expensive in terms of the capital cost of the welding equipment.

With the assistance of Manufacturing Technology Partnership (MTP), the

company approached ITI to investigate solutions. ITI worked through two

initial stages, the first including provisional research into suitable jointing

techniques and five concept designs, and the second taking one

conceptual design using hot air to a more detailed level. The second stage report also offered an

approximate 'time and materials' budget for the work and a review of the technologies

and hardware options best suited to the selected welding concept.

As a result of the above work, ITI was asked to design, manufacture and

commission a Hot-Air Welding Machine for the client company.

The Concept:

The function of the Hot-Air welding machine is to form a continuous weld in

a two layer overlap of Corriboard plastic. The range of Corriboard gauge is

from about 3mm to 8mm. |

| |

|

|

| |

|

The Welding Process |

| |

|

|

The machine operates on the principle of directing a constant flow of

hot-air between and onto the two plastic surfaces to be welded together.

A suitable shaped nozzle tucks between the overlaped surfaces, directing

the hot air through several pre-heat slots and out the end of the nozzle. The

surface layer of exposed plastic becomes molten, allowing the layers to be

fused together by two stages of pinch rollers which follow the nozzle. |

|

|

The material is automatically fed past the nozzle thus forming a continuous

joint. When the flat Corriboard box leaves the machine the weld is sufficiently

cool to maintain the joint against abuse.

Read more about the KBC machine at the MTP

website.

|

| |

|

Back to top |

|

| |

|

|

| |

|

Background:

|

| |

|

|

The client was a manufacturer of a wide variety of trailers for the haulage

industry, including trailers which are constructed on what is known as a

‘lightweight’ chassis. From time to time in the past, the company

had

encountered occasions where these 3-axle lightweight trailer chassis

had

developed cracks at particular points in the welded high-tensile chassis

structures. The company therefore decided to instigate a research exercise to

pinpoint the causes of the localised cracks. |

|

|

|

ITI was approached to assist in the capture of data that could ultimately be supplied

to a Finite Element (FE) model of the chassis to allow fine-tuning of the chassis

design to resolve the material failure problems. To do this ITI had to conceive a means

of instrumenting the trailer sufficiently to capture the pertinent stresses, and a series

of rigorous tests to allow for accurate interpretation of the captured data.

The lightweight trailer was fitted with a total of 20 No. strain gauges, 2 No. air

suspension pressure transducers, 1 No. wheel speed pickup, and 2 No.

inclinometers, all

placed to maximise the useful data obtained. The signals were captured on a notebook

computer during the tests and post processed.

A series of tests was also devised and carried out on the trailer to obtain data suitable for

calibration of the various sensors and to verify any assumptions made.

Three ‘Road Runs’ provided for extensive sets of dynamic test data. The runs

included a ‘chicane’ test, roundabout manoeuvre, rough and smooth road

tests, and tight turns, amongst others. The data obtained from the static tests provided

the basis for correct interpretation of the data observed during the dynamic tests.

An immense amount of valuable information was obtained from the above work, much

of which could be applied to improve the chassis design with or without the use of FE

modelling.

The graph shown below is a short extract from the second Road Run (dynamic testing),

showing the measured stresses in the top & bottom leaf-spring strain gauge sets

both nearside and offside. Numbered points are highlighted where particular road

features correlate with data. The bottom trace on the graph

indicates the trailer speed

(km/hr).

- Feature 1

- Tight left turn at 10 km/h and stationary for 22 seconds

- Feature 2

- Tight right turn at 5 km/h

- Feature 3

- Tight right turn at 18 km/h

- Feature 4

- Tight left turn at 20 km/h

- Feature 5

- Tight left turn at 15 km/h

|

| |

|

Back to top |

|

| |

|

Copyright © Innovation Technologies (Ireland) Ltd 2001-2004 |